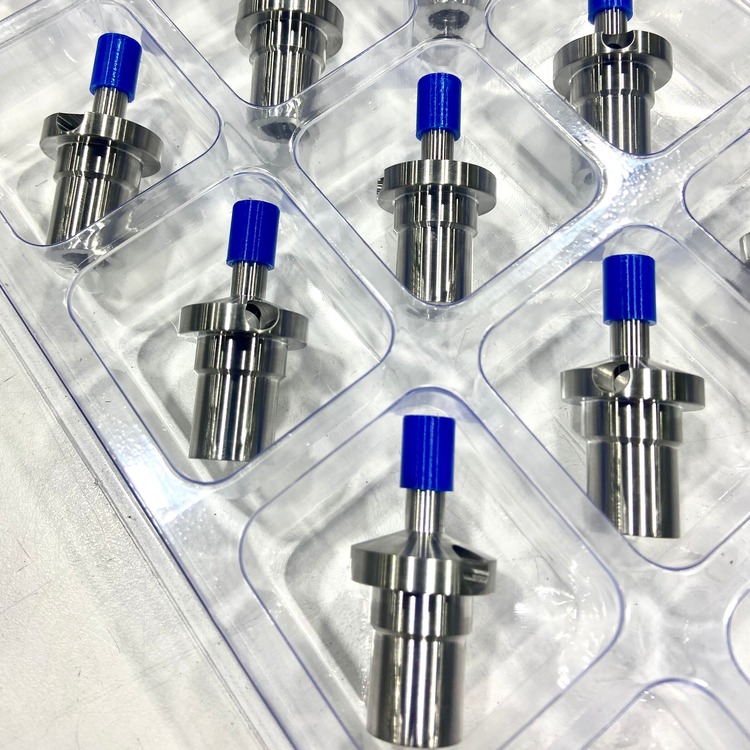

We have WEAPONIZED the WAR against FOD

A Trusted Partner In Burr Free Precision Since 1990

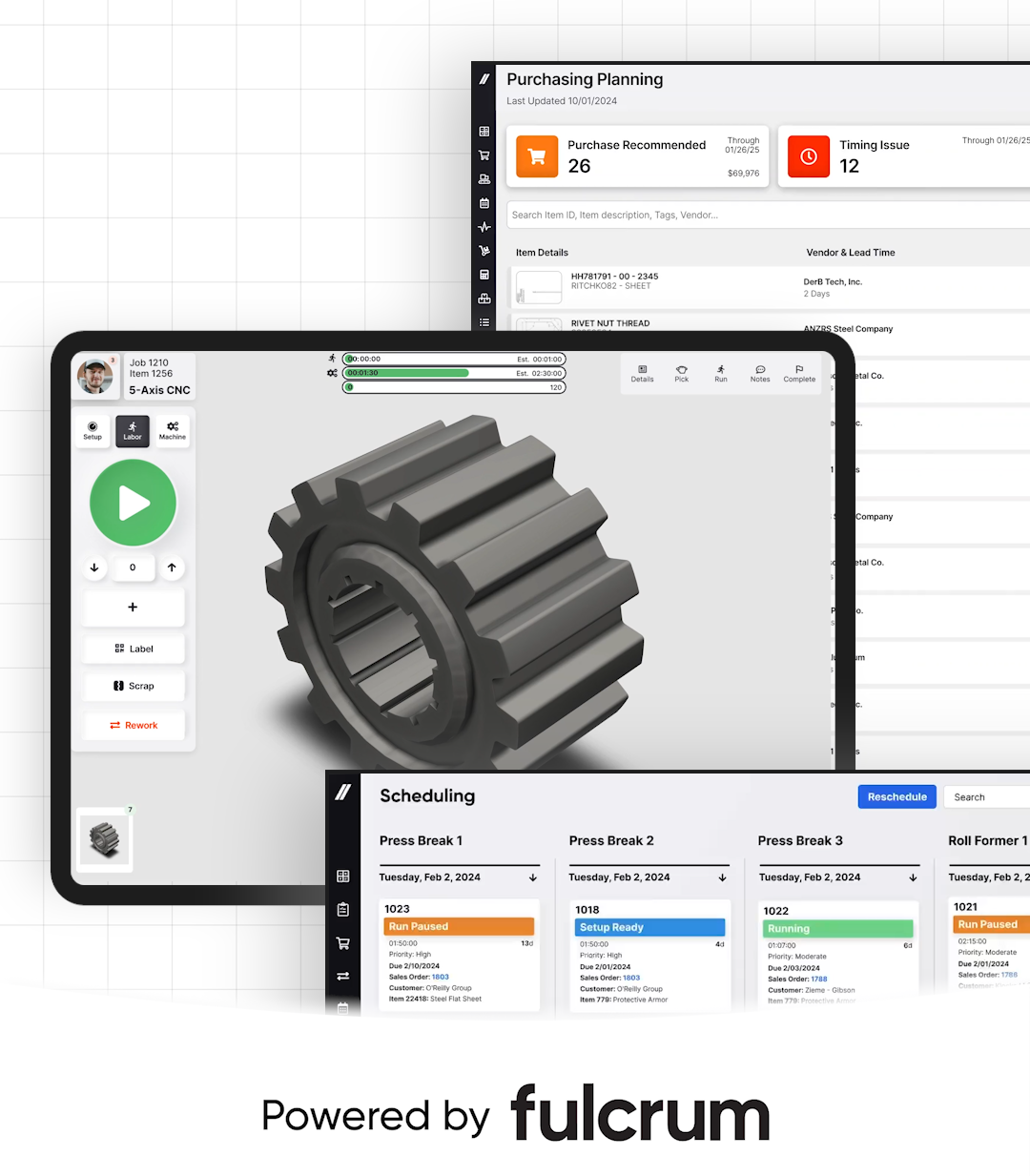

Digital Connectivity

Traceability, Accountability, Complete Production Control For Precision Machined Parts

Industries Served

The Customer’s Strategic Link in the Domestic Supply Chain

The Engineer's Machined Part Advisor

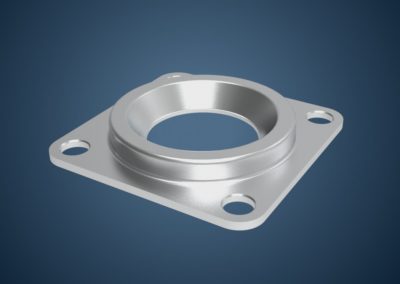

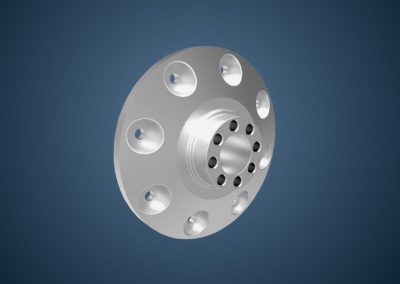

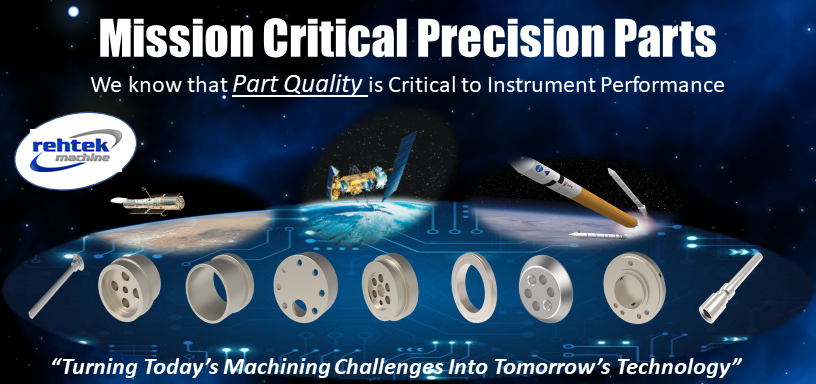

We are an AS9100 Registered Multi-Task Machining Company that excels at reducing costs and delivering high quality, precision CNC machined parts that are paramount to your quality finished product.

The quality of your mechanical part is our primary focus.

Lean Process Flow and Efficiency to Reduce Costs

Ensures that your schedule is met and the most cost effective methods are used to produce your precision machined parts.

This is what we call the pro–tek® process The pro tek process from rehtek machine

Meeting your part requirements is of vital importance to us, which is why our manufacturing engineering staff will discuss with you the Critical To Quality design elements of your parts.

We are committed to lending our expertise and years of experience in manufacturing precision mechanical components to lower costs for both your new designs and mature products.

Our Facilities

Our Capabilities