Space

PRECISION MACHINED PARTS FOR THE SPACE INDUSTRY

Rehtek Machine is AS9100D Registered, a trusted vendor in the space industry, specializing in machining precision parts for over 30 years. We work with only the highest quality space alloys and our world-class machine shop adheres to the tightest tolerances when it comes to CNC machining. Our team of manufacturing engineers, machinists and operators excel at meeting your dimensional tolerancing, cosmetic appearance and the “microscope serves as our eyes” on FOD removal. We understand how critical it is to develop innovative sensors that allow for successful launches and orbits during the most innovative space time. Rehtek’s experience and product portfolio qualifies us for the increasing precision and control needed for the increasing requirements of the Space industry.

SPACE ALLOYS

Spaced alloys are raw materials designed specifically for the space field because they can hold up in very harsh intense environments. The application and environment of these alloys in high performance requirements, high heat of propulsion systems, space engines, and gas. These alloys need to be lightweight, yet durable and strong enough to support something.

We work with the following aerospace alloys:

- Inconel

- Titanium

- Aluminum 6061

- Stainless steel

- Invar

- Hastelloy

- Monel

- Nickel

- Alloy 42/52

- Powdered Metals

- Molybdenum

- Nitralloy

COMPONENTS AND PARTS

Rehtek has the capability to machine alloys into many different components and parts for space applications.

Some examples include but are not limited to:

- Shock mounts

- Valves

- Housings

- Nozzels

- Pressure sensor

- Propeller components

- Testing equipment

- Regulators

- And more!

PRODUCT TRACEABILITY

Our Enterprise Resource Planning System, or ERP, is done through Shoptech MFG. This software platform allows us to digitalize our entire process, from estimate to quote, machining to final inspection, all the way to billing. Every step is completely controlled and contained within this ERP, making your product 100% trackable and traceable.

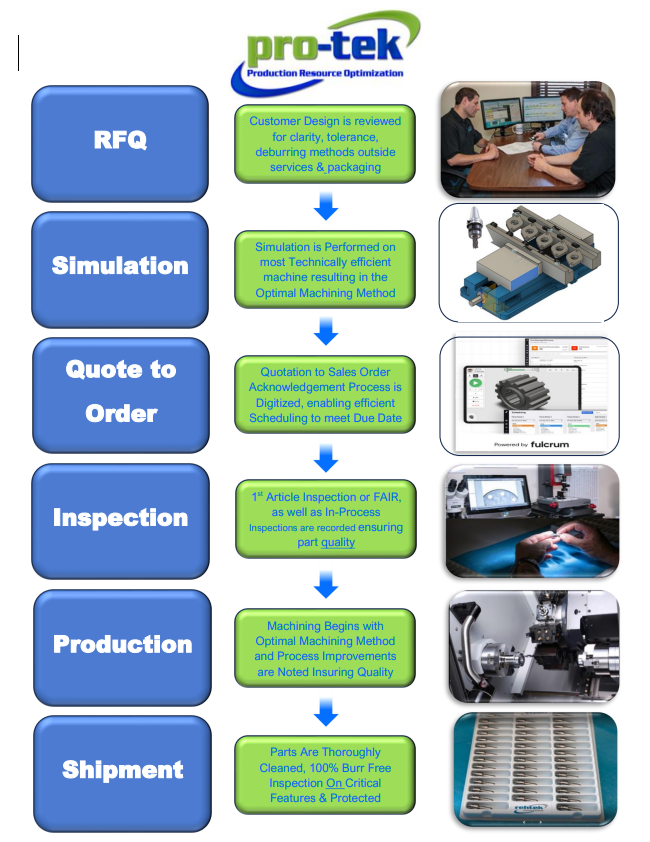

OUR MACHINING PROCESS

Rehtek’s exclusive pro-tek® process optimizes every aspect in the manufacturing of your part.

Since 1990 we have developed and implemented a continuous feed loop noting critical part features across multiple industries. Every part is Unique but we have the tools to value stream map your machining process to reduce your total acquisition cost.

Leveraging our 30 plus years of Intuitive Machining Expertise, our dedicated team of skilled manufacturing engineers will elevate the quality of your parts!

CERTIFICATIONS

- ISO9001:2015 Registered

- AS9102 1ST Article Inspection (FAI)

- CAGE Code 58RB4

- NAICS 332710, 332721, 325920

- DUNS #602829616

MACHINING CAPABILITIES

- Work envelope .010” to 10.0” Dia

- High production gang tooling

- Multi-task turn-mill centers

- Hyper-productive turn-mill centers

- Palletized milling and drilling

- CNC Hybrid

- CNC Swiss Machinery

- Glass Bead Blasting

POST MACHINING OUTSIDE SERVICES

- NADCAP Certified Subcontractors

- Anodizing

- Chem Film

- Hard Coating

- Heat Treatment