Parts Expertise

SINCE 1990 REHTEK HAS SERVED THESE INDUSTRIES WITH PRECISION MACHINED PARTS

SPECIALIZED SERVICES TO MEET YOUR SPECIFIC NEEDS

Rehtek provides a broad range of machining services to a wide variety of different industries, meeting all of the necessary industry specific requirements and certifications.

Our robust documentation procedures ensure that thorough records will be created and saved for every part of the process.

3D modeling services are also available to further streamline your engineering and manufacturing process.

Learn more about some of our specialties and areas of expertise using the links below.

Experience the Expertise

PARTS EXPERTISE

AVIONIC MOUNTS

AVIONIC MOUNTS

SENSOR COMPONENTS

SENSOR COMPONENTS

VALVE COMPONENTS

VALVE COMPONENTS

OEM

OEM

MACHINING SPECIALTIES

CNC MICRO

CNC MICRO

CNC MILLING

CNC MILLING

CNC MULTI-TASK

CNC MULTI-TASK

CNC HYBRID

CNC HYBRID

CNC SWISS

CNC SWISS

CNC HYPERPRODUCTIVE

CNC HYPERPRODUCTIVE

REHTEK SPECIALIZES IN PRECISION PARTS MACHINED FROM METALS AND EXOTIC ALLOYS

“WHERE TODAY’S MACHINING CHALLENGES BECOME TOMORROW’S TECHNOLOGY”

SENSORS

We specialize as a niche supplier to the sensor industry, we have precision equipment dedicated to making parts from .005″ Diameter to 1.0″ specifically for the sensor industry.Our “eyes on quality” for the sensor industry are microscope and the operator’s micrometer. We pay strict attention to critical part edges handling to ensure a quality hermetic seal. The skilled personnel at REHTEK know that dimensional tolerancing, as well as cosmetic appearance, is key to high performance sensors.

We maintain an inventory of Kovar, 52 Alloy, and Inconel, ready rapidly respond to customer needs. Microscopic deburring in the norm and we run drills thru all holes 100% as part of final processing to ensure a quality glass to metal seal body. Contact us for a consult or price comparison for all or your sole source sensor components. We know what you need.

ENERGY

Energy OEMs have relied on Rehtek Machine for complex and precision parts since 1990. At Rehtek, we have developed a proactive machining expertise specific to OEM’s. We help customers reduce the number of components in an assembly. Parts with multiple features are remodeled with our multi-task machining capability by combining two parts into one. Rehtek offers industry customers the advantage of reduced costs, quick deliveries to keep equipment running. We can also supply bar coded spare part kits to their end users.

In energy industry applications we multi-task machine components and assemblies for precision parts for oil and gas processing, solar and wind harnessing. We welcome the chance to face the challenges of energy industries and look forward to machining your precision parts and assembled components needs.

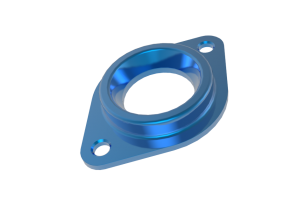

SHOCK MOUNT INDUSTRY

The Shock Mount Industry relies on Rehtek Machine for “Done In One” precision parts that are turned and milled in one operation. With our machining expertise we offer cost sensitive precision parts. Rehtek machines components for assemblies such as Aerospace Mounts, Military Applications, Racing Shock Mounts, After Market and Replacement Mounts. We contract manufacture with out customers shipping out finished mount assemblies at lower costs.

For the high performance aftermarket we machine custom hubs, sprockets and pulleys to withstand high stress and pressure. We look forward to producing your precision parts and assembled components needs.

OEM’S

Today’s OEMs rely on Rehtek Machine for quick turnaround of complex precision parts. At Rehtek, we developed a proactive machining expertise specific to OEM’s. We help customers reduce the number of components in an assembly. Parts with multiple features are remodeled with our multi-task machining capability by combining two parts into one. Rehtek offers industry customers the advantage of reduced costs, quick deliveries to keep equipment running. We can also supply bar coded spare part kits to their end users.

Today’s Consumers are trending toward “Made in the The USA” and we are here to keep it Made In America, your dollar will go a long way!

VALVES

The Valve Industry relies on Rehtek for precision parts including rings, valve seats, seals, nozzles, and discs. We machine exotic alloy parts to withstand the harshest of environments as well as high and low viscosity applications. Our precision machining experience has given fluid power manufacturers the advantages of a microscopic eye on quality with great attention to precision and sealing surfaces. We are able to multi-task machine many complex parts.

We are able to multi-task machine many complex burr free features within the machining cycle for the valve industry. Customers have relied on us to deliver parts ranging from .005″ to 5.0″ in diameter for all aspects of valve component parts.

HYDRAULICS

Hydraulic and fluid power OEM rely on Rehtek Machine for complex and precision parts which are machined with precise attention to sealing surfaces. Since 1990 Rehtek has developed the machining knowledge and expertise utilizing the latest in machining and inspection technology Our shop floor personnel employ their machining expertise and knowledge utilizing the latest technologies. Rehtek offers hydraulic industry clients the best in close tolerance precision parts. Our experience and knowledge of precision machining gives our customers the advantages of reduced costs, better production time, and skilled labor.

In the hydraulic industry, we service components and assemblies for lift systems, pistons, end caps, manifolds, shafts, and other widely used machined parts used in the industry. We welcome the chance to face the challenges of hydraulic industries and look forward to producing your precision machined parts and assembled components needs.