Sensor Industry

Bodies, Headers, Feed Thrus

Hermetic Seal Surfaces

Sealing Process Knowledge

Micro Drilling .007+Dia

Sandblasting & Surface Treatment

.032 to .042 Tapered Holes

Kovar 52Alloy Inconel

Palletized Fixturing

Microscopic deburring

Sensors Industry Expertise

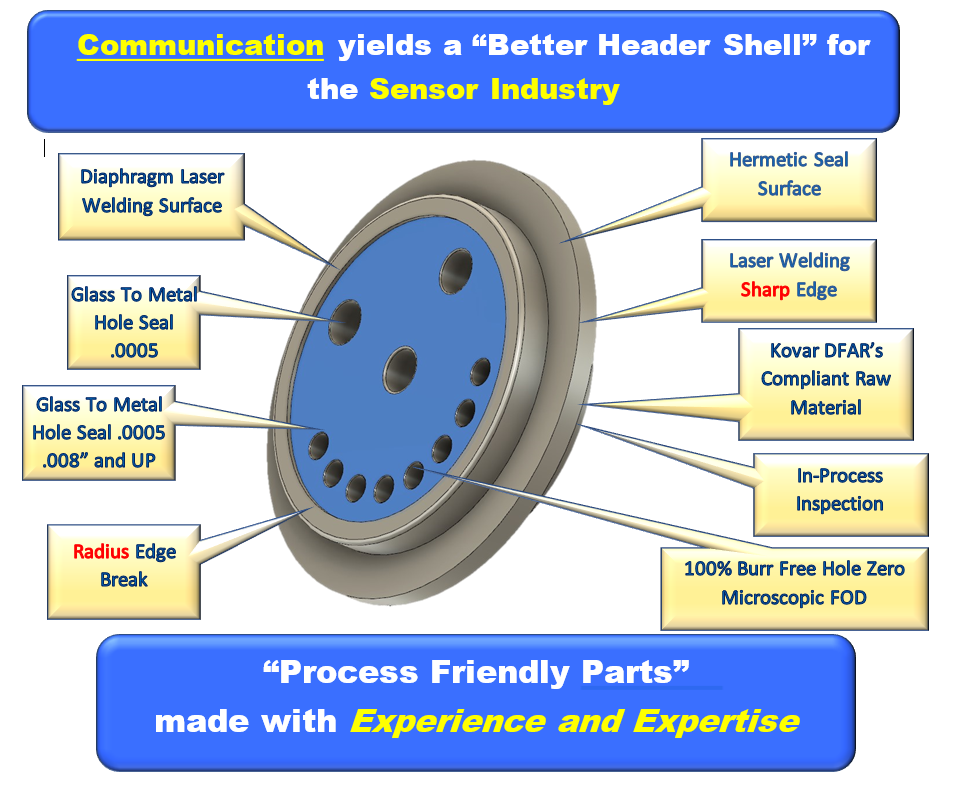

Process Friendly Header Shell

We understand the glass to metal sealing industry and that header shells have critical to process features. We pay close attention to hermetic seal surfaces, laser beam welding process, burr and nick free surfaces insure a quality seal. We have experience and expertise in machining kovar, stainless, titanium and inconel.

Header Shell with Braze Hole

Header shell with braze hole +.0005-0000 close fit tolerance ensuring capillary actions for brazing of tubes and glass wire seals. We maintain tight tolerences on depths and diameters so your parts flow thru the sealing process

Creativity In Header Shells

We understand the glass to metal sealing industry and that header shells have unique features. We pay close attention to critical to quality function surfaces to insure a quality seal. We have experience and expertise in machining kovar, stainless, titanium and inconel.

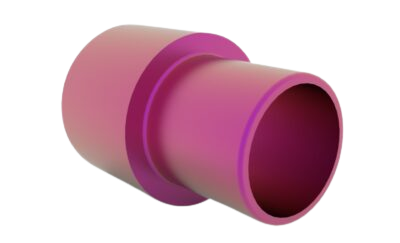

Feed Thru Shell

We understand the glass to metal sealing industry and that feed thru shells have critical wall thicknesses. We are able to machine .003 wall thickness on turn part .125 diameter in kovar and stainless steel.

Inconel Port with UNJ Threads

We have the teachnical skills to machine and hold size on inconel ports with critical sealing surfaces.

PRODUCT TRACEABILITY

CERTIFICATIONS

- AS9100D

- AS9102 1ST Article Inspection (FAI)

- CAGE Code 58RB4

- NAICS 332710, 332721, 325920

- DUNS #602829616

MACHINING CAPABILITIES

- Work envelope .010” to 10.0” Dia

- High production gang tooling

- Multi-task turn-mill centers

- Hyper-productive turn-mill centers

- Palletized milling and drilling

- CNC Hybrid

- CNC Swiss Machinery

- Glass Bead Blasting

POST MACHINING OUTSIDE SERVICES

- NADCAP Certified Subcontractors

- Anodizing

- Chem Film

- Hard Coating

- Heat Treatment

SENSOR INDUSTRY RAW MATERIALS

Sensor raw material alloys are designed specifically for the sensor field because they can hold up in very harsh, intense environments, for example, the high heat of a jet engine or a caustic, corrosive chemical application or extreme pressure of hydraulic systems. These raw materials are specific to the glass to metal sealing industry as well. These alloys need to be dynamic, functional, durable, and strong enough to function in the harshest environments

Machining expertise with the following sensor raw materials:

- Inconel

- Titanium

- Kovar

- Stainless steel

- Invar

- Hastelloy

- Monel

- Nickel

- Alloy 42/52

- Copper

- Molybdenum

- Nitralloy

SENSOR MACHINING EXPERTISE

Sensors require machined components that have critical to quality and functionality features . These features are specific to the functionality of a high performance sensor. Our sensor machining experience and expertise are our machining niche yielding a precisely controlled machining process. We understand the critical features and machine and deburr components with detailed attention to insure process friendly features used in the glass to metal hermetic sealing process.

Rehtek has the capability to machine various alloys into many different components parts for sensor applications.

Some examples include but are not limited to:

- Headers

- Fittings

- Bodies

- Feed Thrus

- Housings

- Cable Reliefs

- Cover

- Sleeves

- Adaptors

- All Hermetic Seal Surfaces

- Mounts

- Ports

Machining features and characteristics:

- “Done in One” Operation

- The Microscaope Serves as our Eyes

- Hermetic Sealed Surfaces

- Sharp .0003R corners

- Precisly Drilled holes .005-.125

- Lapped surface features

- Sandblasting

- Inventory Management

- Controlled Lot Sizes

- Digital Metology Inspection

- Detailed Deburring

- 100% of Critical Features

- Burr Free Holes

- Workmanship Standards

- Customer Communication

Kovar Header Shell .030 Dia Cross Holes